High speed

LGS High speed elevator use very advanced technology to realize optimum performance and fficiency. hese advances include the high-efficient permanent magnetic gearless traction machine with dual disk brake, VVVF inverter, Artificial Intelligence, and Data Network System. Optional features and functions including energy-saving regenerative drives and destination dispatching control are available to improve passenger safety and comfort and simplify building management.

Middle & Low speed

LGS Middle & Low speed elevators are applicable to luxury residential building, hotel, office building, commercial building, etc. They can reduce energy consumption and decrease environmental pollution by adopting the highly efficient permanent magnetic gearless traction machine and inverter control system. Its mini machine room solutions make it easy to give flexibility of building design requirements. They also have a variety of excellent aesthetics designed by Korean professional elevator designer while keeping customized options.

MRL

LGS machine roomless elevator can optimize building space with efficient shaft utilization. In addition, there is no construction cost for building machine room, which makes it possible to design a flexible building design. High-efficient traction machine and advanced variable frequency drive systems can save more than 30% of energy consumption compared to traditional traction elevator.

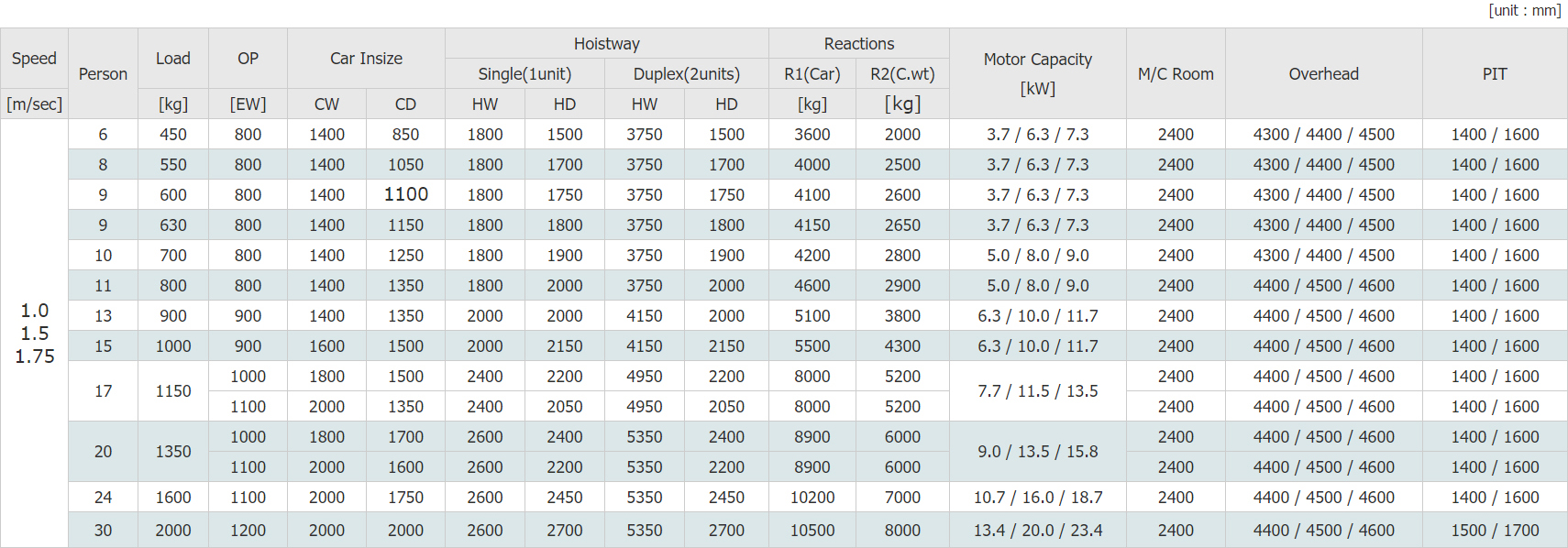

PLANNING GUIDE MMR(Mini Machine Room) Gearless

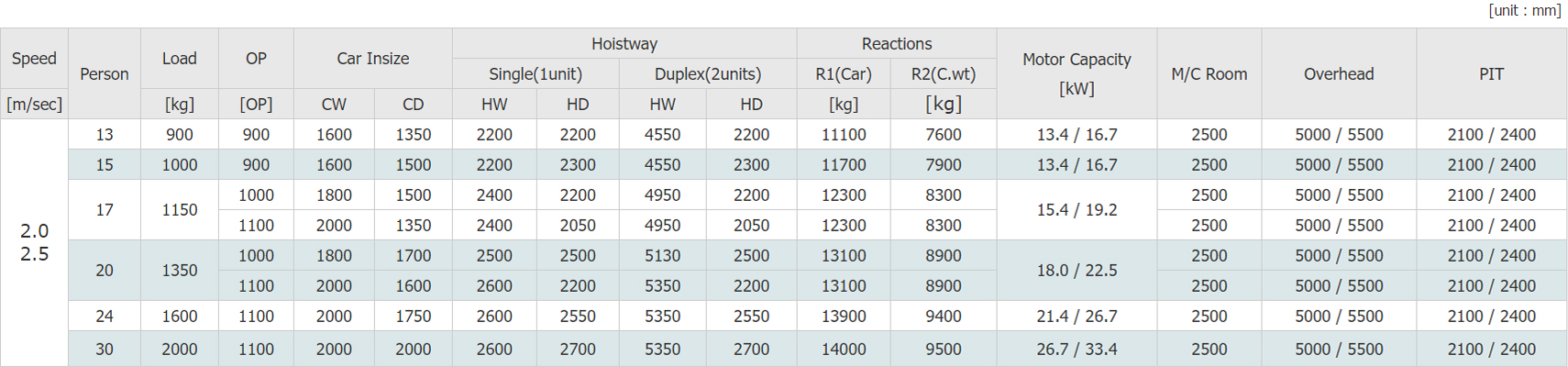

PLANNING GUIDE MRL(Machine Room Less)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Passenger Elevator (Speed 1.0~1.75m/s)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Passenger Elevator (Speed 2.0~2.5m/s)

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Note. 1. Above dimensions in table shall

be under the following conditions 1) Door opening : 2panel Center opening (2P-CO), 2) No. of Door in Car : 1Car 1Door 2. OH, PIT dimensions shall be under the following condition Entrance Height : 2100mm, Cab Height : Manufacturer's standard 3. Single hoistway (*) for 3.5m/s and 4.0m/s shall not be allowed.(should be Duplex Hoistway) |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Passenger Elevator (Speed 3.0~4.0m/s)

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Note. 1. Above dimensions in table shall

be under the following conditions. 1) Door opening : 2panel Center opening (2P-CO) 2) No. of Door in Car : 1Car 1Door |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machine Roomless Elevator(MRL)

| Feature | Description | Remark |

| Full collective selective | In automatic running or attendant state,

this function enables the elevator to respond both car calls and hall

calls. Passengers at any service floor can call the elevator by pressing the up call button and down call button. |

● |

| Anti-nuisance function | The system automatically judges the number

of passengers in the car and compares it with the number of registered

car calls. If there are excessive car calls, the system determines that it is nuisance and cancels all car calls. In this case, passengers need to register correct car calls again. |

● |

| Car Call Cancellation | Passengers can press the button consecutively twice to cancel wrong calls. | ● |

| Turn Off of Car Light and Fan |

If there is no running command within the set time, the system automatically cuts off the power supply to the lamp and fan in the car. | ● |

| Full-load direct runnung | When the car is full-loaded in automatic

running state, the elevator does not respond to hall calls from the

passing floors. These halls calls, however, can still be registered, and will be executed at next time of running (in the case of single elevator) or by another elevator (in the case of parallel/group control). |

● |

| Overload protection | When the car load exceeds the rated elevator load, the elevator alarms and stops running. | ● |

| Button stuck check | The system can automatically identify

whether a hall call button is stuck and cancel the stuck call, preventing the condition that the elevator cannot close and run due to stuck hall calls. |

● |

| Repeat door close | If the door lock is not applied after

the elevator performs door close for a certain time, the elevator

automatically opens the door and then closes the door again. |

● |

| Automatic door open upon door lock abnormality |

If the system detects that the door lock

circuit is abnormal during door open/close, the elevator automatically

opens and closes the door again, and reports a fault after the set door open/close times is reached. |

● |

| Door open time setting | The system automatically determines different

door open time for door open for call, command, protection, or delay according to the set door open holding time. |

● |

| Arrival gong disabled at night | Within the set time period, the arrival gong is disabled. | ● |

| Landing at another floor | If the door open time exceeds the door open protection time but the door open limit signal is still inactive, the elevator closes the door and then automatically runs to the next landing floor. | ● |

| Voice Announcement | The elevator automatically announces information

such as the running direction and next arriving floor during running. |

● |

| Forced door close | When the door fails to close within the

set time due to the action of the light curtain or safety edge, the

elevator enters the forced door close state, closes the door slowly, and gives a prompt tone. |

● |

| Group control | The system supports parallel control of two elevators / group control of more than three elevators | ○ |

| Micro Leveling | After landing at a floor, the elevator

may move upward or downward due to the load change and the car door

is not aligned with the ground, which is inconvenient for in and out of passengers and goods. In this case, the system allows the elevator to run to the leveling position in the door open state at the leveling speed. |

○ |

| Light curtain signal judgment | If the door is blocked by stuff during door close, the light curtain acts and the elevator opens the door. This function is invalid in fire emergency state. | ○ |

| Power failure emergency evacuation |

For the elevator configured with standby

power supply, the system uses the standby power supply (ARD System)

to implement low-speed self-rescue in the case of power failure. |

○ |

| Residential monitoring | The control system can be connected to

the terminal in the monitoring room. By using the NEMS software, you can view the floor position, running direction, and fault state of the elevator. |

○ |

| Parking Operation | In order for park the elevator, if the

parking key is on position the car stop at the specified floor after

finish servicing of all of registered call. After the car stops at the specified floor, the car light and fan are off automatically and every buttons both on the car operating panel and hall button box are no more available. |

○ |

| Fire return Operation | In case of fire every cars should be returned to the specified floor in order to evacuate passengers safety. | ○ |

| Fireman Operation | In case of fire, a fireman can use the elevator which is stopped at the specified floor in order to support fireman for fire-fighting. | ○ |

The works below are not included in the elevator installation work and should be carried out by building contractors in accordance with our drawing, relevant international or codes and regulations.

-A property framed and enclosed hoistway, including any ventilation as required by the governing code or authority.

-A dry pit constructed to the elevator manufacture's specifications to reinforce or sustain any vertical forces on the guide rails impacted loads from the car and counterweight buffers.

-A metal still angle or concrete haunch across the full width of the hoistway at each elevator landing.

-Provision of steel bars to fix jamb around the entrance of each floor.

-All cutting, including cutouts to accommodate hall signal fixtures, patching, painting of wall, floors, or partitions, together with finish painting of entrance doors and frame, if required.

-Provision of entrance or ladder for pit access.

-Supply and installation of fascia plate

-Installation of emergency exits and electric wiring in blind sections of hoistway where required.

-the tolerance of emergency exits and electric wiring in build sections of hoistway where required.

-The tolerance of perpendicular line over the whole hoistway height must not exceed ±30mm.

-A waterproof outlet and light fixture in the elevator pit area with the light switch being located adjacent to the access door ladder.

-Suitable light fixture and convenience outlet in the pit with a light switch adjacent to the access door or ladder. The receptacles shall have protection for ground.

-Provision of wiring between controller and building management system.

-A construction hoisting beam or hook, if require, with the correct location and size as determined by elevator contractor for each hoistway.

-Noise insulation should be installed between machine room and adjacent residential area.

-A suitable machine room with legal access, ventilation and concrete floor . The temperature in the machine room should be maintained between 5℃ and 40℃ Relative humidity should not exceed 90%(monthly) and 95%(daily) non-condensing.

Ventilation fan or air conditioner should be provided as per heat dissipation by the elevator contractor.

-The size of entrance shall be min. 1000mm(w) X 2000mm(H).

-Installation of lead-in wire and earth wire between building main power board and room incoming distribution board. However, machine room lighting source supply shall be install separately.

-Provision of suitable light fixture and convenience outlets in the machine room.

-Wiring and piping between each machine room and monitoring system.

-Machine room and hoistway shall be free or harmful gas.

-All electric power for lighting, tools, welding, etc during installation.

-All single phase receptacles installed in machine room, pit and machinery spaces shall ground fault circuit interrupter

-Fire detector for emergency operation.

- A secured area for storage of elevator equipment and materials during installation.